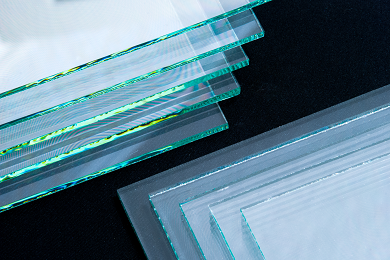

In the manufacturing process of flat glass used for building materials and automotive glass, it is produced by a method called the float method, in which molten glass floats on a tank (molten bath) of tin. The refractory of the molten metal bath corrodes during long-term use, so it is also necessary to monitor the thickness of the refractory. When the refractory is corroded, the surface temperature of the steel casing becomes high. To monitor the corrosion condition temperature of molten metal bath metal casing can be measured.

Solution

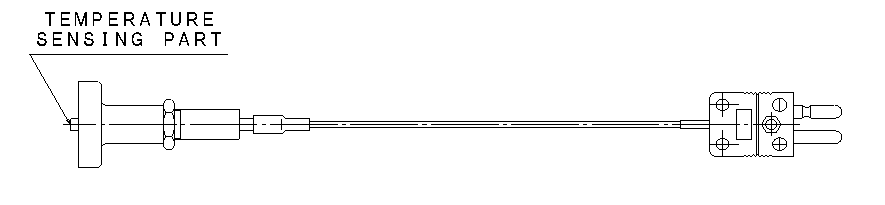

Sensor with magnet for measuring tin tank surface temperature

- Daily life

- Automobiles

- High temperature

Features

Measuring the temperature of the steel casing of the molten metal bath verifies the integrity of the refractory. The magnetic mounting method enables the installation in a free location on the steel casing, enabling a more accurate understanding of the wear and tear points of the refractory. The magnets we use are less susceptible to deterioration of magnetic force even at high temperatures, and are used in a wide range of applications, including manufacturing processes in the steel industry.