Continuous casting equipment is used to make steel products with a fixed shape by continuously pouring molten metal into a mold and letting it solidify. The mold is made of copper and is always cooled with water. When the molten steel touches the mold, it solidifies under carefully controlled cooling.

To detect early signs of breakouts (BO) during the continuous casting process, thermocouples are installed inside the copper plates of the mold to monitor the temperature.

Solution

Sensors for Continuous Casting Molds

- Thermocouple

- Steel & Nonferrous Metals

- Industrial Machinery

- High temperature

- Furnace

Features

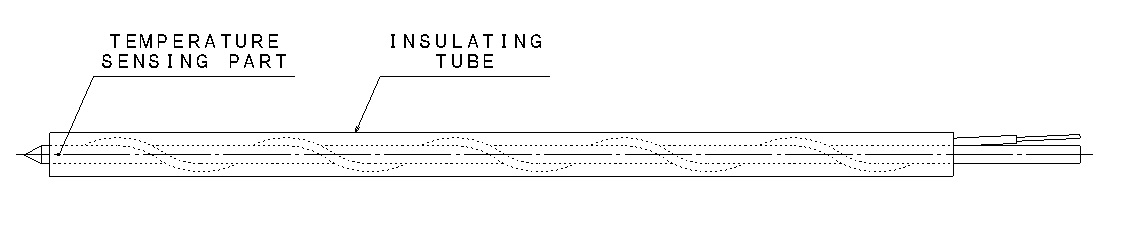

To reduce noise, a twisted type has been selected and adopted.

In addition, we can also propose a tip CAP type, which has good temperature response of the copper plate and improves ease of installation in the equipment.