Knowledge

High temperature thermocouple

Wire of high-temperature thermocouple (HT-THERMIC)

Tungsten-rhenium-based wire (C) is used at temperatures up to 2000℃ and platinum-rhodium-based wire (B) is used at temperatures up to 1800℃ depending on the measured temperature and temperature of the thermocouple for high-temperature use (HT-THERMIC). Special wires such as Pt and 5% Mo-Pt・0.1%Mo, Ni・18%Mo-Ni can also be used for special environments such as nuclear power.

C (W•5%Re-W・26%Re) •Compatible atmosphere: Reduction, Inert, Vacuum, Nuclear Environment

Tungsten 5% Rhenium-Tungsten 26% Rhenium thermocouple wire was developed with the aim of preventing embrittlement by adding Rhenium to both legs and greatly improving mechanical strength. This thermocouple wire does not become embrittled even when heated to 1650℃, and can be annealed. This eliminates the issue of shifting in the early E.M.F and prevents wire breakage during use. As a result, it is becoming the mainstream of tungsten-rhenium thermocouples.

Thermoelectric power up to 0 to 900℃ has good linearity. This thermocouple has a good track record in use even in high-temperature nuclear environments.

Tungsten-rhenium alloys are easily oxidized and cannot be used in air or other oxidizing atmospheres.

B (Pt・30%Rh-Pt · 6%Rh) · Compatible atmosphere: oxidized, inert

A thermocouple using a Pt・Rh alloy containing Rh(30% in the (+) pole and a Pt・Rh alloy containing Rh (6%) in the (-)pole. Thermocouples are designed to increase the melting point and mechanical strength as the rhodium content of platinum increases, and to prevent degradation of the thermoelectromotive force due to the diffusion of (Rh) from the (+) pole to the(-)pole that occurs during the use of R and S thermocouples. In addition, it can be used continuously in oxidizing and neutral atmospheres, and even in a reducing atmosphere, it generally has a longer life than R thermocouples.

Using high-purity alumina (99.5% or more) material for the protective tube and insulation tube. Handle the thermocouple with care, and use alcohol or benzene to remove any dirt that may be contaminated by perspiration or oil.

Since rhodium in alloy components has a large neutron absorption cross section and is converted to palladium in a short period, it is not suitable for measuring nuclear environments.

Characteristics of thermocouple wire

| Model number | Type | Temperature measuring range | Melting point | Coefficient of thermal expansion | Electric resistivity (μΩ /cm) At0~100℃ |

|---|---|---|---|---|---|

| C | W5%Re | 0~2300℃ | 3350℃ | – | 18.0 |

| W26%Re | 3120℃ | 3.9×10-6/20~1983℃ | 30.9 | ||

| B | Pt30%Rh | 600~1700℃ | 1927℃ | 8.9×10-6/20~1800℃ | 19.0 |

| Pt6%Rh | 1826℃ | 9.1×10-6/20~1800℃ | 17.5 |

Insulating tube of a high-temperature thermocouple (HT-THERMIC)

Solid sintered insulation tubes are used for powder insulation materials such as magnesia and alumina at high temperatures of 1200℃ or higher because the insulation resistance drops rapidly. Generally, the insulation resistance of a solid insulation tube is about 10 times higher than that of a powder insulation of the same quality. HT-THERMIC mainly uses high-purity alumina and beryllia sintered insulated tubes to prevent wire breakage due to thermal stress.

Outline of characteristics of insulation tube

| Model number | Type | Purity | Upper category temperature | Melting point(℃) | Specific heat (Cal g/°C) At20~1000℃ |

Thermal Conductivity (cal・cm-1・℃-1・S-1) At1000℃ |

|---|---|---|---|---|---|---|

| PS0 | Recrystallized alumina | Al2O3 99.7% or more | 1800℃ | 2050±20 | 0.26 | 0.014 |

| BE | Recrystallized beryllia | BeO 99.5% or more | 2200℃ | 2550±20 | 0.50 | 0.046 |

| MG | Burning magnesia | MgO 99.5% or more | 2200℃ | 2800±20 | 0.25 | 0.016 |

(NOTE)The maximum operating temperature represents the refractoriness of the insulator. To use as an insulation tube, it is necessary to consider the insulation resistance characteristics at the operating temperature. Please consult us when using the product near the maximum operating temperature.

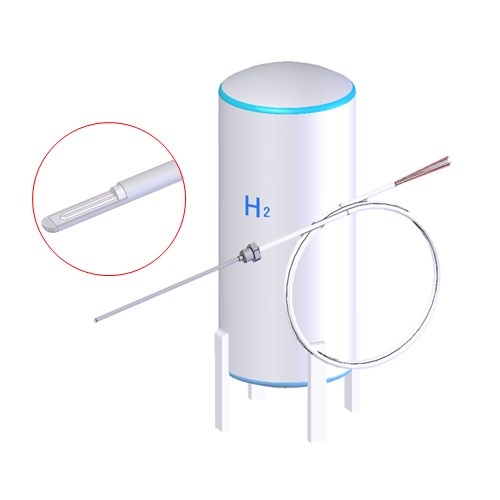

Protective tube for high-temperature thermocouple (HT-THERMIC)

It is well known that the most important point in determining thermocouple reliability and longevity is the proper selection of the protective tubing material. However, high temperature measurements in special environments where complex chemical reactions may occur between the thermocouple material and the thermocouple material require a high level of knowledge to select the material.

Outline of characteristics of protective tube material

| Model number | Type | Melting point (℃) | Coefficient of linear expansion(×10-6) | Thermal Conductivity (cal・cm-1・℃-1・S-1) at1000℃ |

Upper category temperature (℃) | Compatible atmosphere |

|---|---|---|---|---|---|---|

| MO | Molybdenum(Mo) | 2622±10 | 7.2 (at 2000℃) | 0.328 | 1900 | V・R・N |

| TA | Tantalum (Ta) | 2850±10 | 6.6 (at 2000℃) | 0.130 | 2200 | V・N(Ar・He) |

| NB | Niobium (Nb) | 2415±15 | 9.0 (at 2000℃) | 0.132 | 2000 | V・N(Ar・He) |

| PT0 | Recrystallized alumina(Al2O3) | 2050±20 | 8.6 (at 1000℃) | 0.014 | 1800 | R・N・O |

| BE | Recrystallized beryllia (BeO) | 2550±20 | 8.9 (at 1000℃) | 0.046 | 2200 | V・R・N・O |

| ZR | Airtight zirconia(ZrO2) | 2300±20 | 10.0 (at 1000℃) | 0.010 | 2200 | N・O |

(NOTE)V: Vacuum R: Reduction N: Inert O: Oxidative

Stability of Metals for High Temperature in Various Furnace Atmospheres

| Atmosphere | Molybdenum | Tantalum | Niobium |

|---|---|---|---|

| Gas containing air or oxygen | Oxidation at 400℃ to 500℃ Vigorous evaporation above 800℃ |

Oxidation and nitride formation above 500℃ | Oxidation and nitriding at temperatures higher than 200℃ |

| Dry hydrogen(including about 0.5g of water per 1mm2) | Without oxidation to the melting point | Hydride formation at 400℃ to 800℃ Surface oxidation without corrosion to melting point |

Absorption of hydrogen from 200℃ Hydride formation and oxidation at 1900℃ |

| Hydrogen containing water(including water of about 20g per 1mm2) | No oxidation up to 1400℃, needle-like crystal formation on surface thereafter, weight loss | Hydride formation, remarkable oxidation above 450℃ | Absorption of hydrogen from 200℃ Hydride formation and oxidation at 1900℃ |

| Disassembly and drying Ammonia gas |

Without corrosion to the melting point | Nitride and hydride formation above 400℃, complete nitridation at higher temperatures | Hydride and nitride formation at 200℃ or higher |

| Incomplete combustion drying Ammonia |

Without corrosion to the melting point | Nitride and hydride formation above 400℃, complete nitridation at higher temperatures/td> | Hydride formation at 200°C or higher and decomposition nitridation of ammonia at 400℃ or higher |

| Such as argon and helium Inert gas |

Without corrosion to the melting point | Without corrosion to the melting point | Crystal growth and embrittlement at 1900℃ in helium. |

| Vacuum Approx.0.113Pa(approx.10-3TORR) Approx.0.0113Pa(approx.10-4TORR) |

Without corrosion up to 1700℃ Significant evaporation above 2150℃ |

Embrittlement due to getter effect Significant evaporation above 2200℃ |

Embrittlement due to getter effect Small evaporation to melting point |

| Compatible Atmosphere | High temperature, reducing gas, inert gas, low vacuum (oxygen-free) | Inert gas, high temperature, high vacuum | Inert gases, high temperature, high vacuum 900℃ in Na, Li |

Stability of Metals for High Temperature in Various Furnace Atmospheres

| Refractory and insulating material | Molybdenum | Tungsten | Tantalum |

|---|---|---|---|

| Graphite | Carbide formation rapidly above 1200℃ | Carbide formation rapidly above 1400℃ | Carbide formation rapidly above 1000℃ |

| Al2O3 | No reaction up to 1900℃ | No reaction up to 1900℃ | No reaction up to 1900℃ |

| BeO | No reaction up to 1900℃ | No reaction up to 2000℃ | No reaction up to 1600℃ |

| MgO | No reaction up to 1800℃ | No reaction up to 2000℃ However, MgO vaporization is remarkable |

No reaction up to 1800℃ |

| ZrO2 | No reaction up to 1900℃ However, Mo vaporization is remarkable |

No reaction up to 1600℃ | No reaction up to 1600℃ |

| ThO2 | No reaction up to 1900℃ | No reaction up to 2200℃ | No reaction up to 1900℃ |

| Sillimanite | No reaction up to 1700℃ | No reaction up to 1700℃ | No reaction up to 1600℃ |

| Chamotte brick | No reaction up to 1200℃ | No reaction up to 1200℃ | No reaction up to 1200℃ |

| Magnesite brick | No reaction up to 1600℃ | No reaction up to 1600℃ | No reaction up to 1500℃ |