Knowledge

Protective tubes for thermocouples

What is a protective tube for thermocouples?

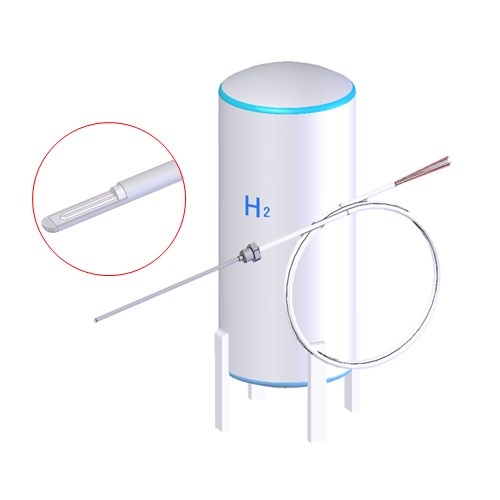

Protective tube for thermocouple is a tube to protect the temperature measuring contact and element wire from direct contact with the object to be measured, atmosphere, etc. It is important to select the optimum protection tube considering the conditions of its use place, and it is an important point of temperature measuring technology. There are two types of protective tubes: metal-protected tube and non-metal-protected tube. Details are shown below.

1. Metal protective tube

SUS304, an austenitic-stainless-steel material, is widely used as a protective tube. In addition, there are many materials such as INCONEL®600, which are highly resistant to oxidation/reduction at high temperatures, and Ti, which is highly resistant to corrosion at low temperatures. It can be used as a protective tube by sealing the tip with welding with a generally standardized pipe. In addition, surface treatment such as stellite treatment is sometimes applied as a measure against abrasion and glass lining as a measure against corrosion.

| Type of material | Model number | Operating Temperature(℃)※1 | Characteristic |

|---|---|---|---|

| SS400 | 400 | Oxidation 600 Reduction 800 |

Weak against acid resistance and oxidation, but strong against reduction |

| SUS304 | 304 | 980 | Excellent heat and corrosion resistance. It is resistant to sulfur reducing gases because it contains Ni |

| SUS304L | 304L | 980 | It is an intergranular corrosion-resistant material with small carbon content of SUS304 (C=0.03% or less)and with small precipitation of Cr carbides which tends to occur by thermal effect of weld. |

| SUS321 | 321 | 980 | It contains Ti and has more corrosion resistance than SUS304. Especially excellent in prevention of intergranular corrosion after welding. |

| SUS316 | 316 | 980 | It contains Mo and is excellent in heat, acid and alkali resistance. |

| SUS316L | 316L | 980 | The C content of SUS316 is reduced, and it is an intergranular corrosion-resistant material. |

| SUS310S | 310S | 1000 | It is a heat-resistant steel with high Ni-Cr content and strong oxidizability at high temperature. |

| SUS347 | 347 | 980 | It contains Nb-Ta, has more corrosion resistance than SUS304, and is excellent in preventing intergranular corrosion. |

| SUH446 | 446 | 980 | It is a heat-resistant material of 27Cr steel. |

| 50Co30Cr | 50 | Oxidation 1150 Reduction 1200 |

It is a Co base alloy which is resistant to heat and abrasion, and is a heat resistant alloy which is also strong to sulfur. |

| INCONEL®600※2 (JIS:NCF600) |

600 | 1050 | It is resistant to either oxidation or reduction atmosphere at high temperature. |

| INCOLOY®800※2 (JIS:NCF800) |

800 | 870 | It is excellent in high-temperature oxidation resistance, and in particular, it has a life approximately 10 times longer than that of SUS304 against high-temperature corrosion. It is also resistant to thermal shock. |

| Kantal AF※3 | KA | 1100 | It is strong for oxidation at high temperature, but it becomes brittle by recrystallization. |

| 80Ni20Cr | NC | 1100 | In high-temperature oxidation atmosphere, both high-temperature strength and corrosion resistance are good, but it is unsuitable for sulfidation atmosphere. |

| Crimax※4 | KU | 1200 | It is an alloy containing 60%Cr and a small amount of W and Nb, Ti, and is excellent in corrosion resistance to molten chemicals and slab gases, and is resistant to metallic attack such as molten copper. |

| Hastelloy B※5 (Hastelloy®) |

HB | Oxidation 500 Reduction 760 |

Ni base alloy with excellent heat and corrosion resistance, and particularly excellent resistance to hydrochloric acid and sulphur. |

| Hastelloy C※5 (Hastelloy®) |

HC | 1000 | Strong against oxidizing and reducing atmospheres at high temperatures and also resistant to chlorine gas. |

| Hastelloy X※5 (Hastelloy®) |

HX | 1100 | Strength is large even at high temperatures, and it is mainly heat-resistant material, and workability and weldability are superior to other hastelloy. |

| Haynes Alloy 25※5 | HY | Oxidation 810 Reduction 980 |

It is a Co base alloy. It is highly resistant to oxidation and fire at high temperatures. |

| Titanium | TI | Oxidation 250 Reduction 1000 |

Excellent corrosion resistance at low temperatures, but is oxidized and brittle at high temperatures. |

| Monel※2 (Monel®) |

MN | Oxidation 500 Reduction 600 |

It consists of Ni67~70% and Cu-Fe, and is resistant to high temperature and high pressure and has excellent corrosion resistance. |

| Tantalum | TA | Oxidation 300 Reduction 2200 |

It is a heat-resistant material resistant to many acids, but it becomes brittle at high temperatures in air. |

In addition, we also handle protective tubes made of special materials.

※1 operating temperature varies depending on the atmosphere.

※2 Inconel®, Incoloy® and Monel® are registered trademarks of Special Metal Corporation.

※3 Kanthal AF is a registered trademark of KANTHAL.

※4 CRIMAX is a registered trademark of Kurimoto Tekko Co., Ltd.

※5 Hastelloy® and Haynes Alloy 25 are registered trademarks of Haynes International, Inc.

2. Non-metallic protective tube

Materials used as non-metallic protective tubes include alumina(Al2O3), which is excellent in high-temperature strength, electric insulating properties and abrasion resistance, silicon carbide, which is superior in thermal conductivity and rapid heating, and silica glass, which is highly resistant to thermal shock by rapid cooling, and silica glass, which is highly acid resistant. It is mainly used as a protective tube for thermocouples for high-temperature measurement.

| Type of material | Model number | Operating Temperature(℃)※1 | Characteristic |

|---|---|---|---|

| Quartz glass | QT | 1000※2 | It is transparent and opaque, and the former gets a little bit of heat resistance. It can withstand quenching and rapid heating, but its strength is small. Weak to alkali and strong to acid. It is inferior in gas tightness to hydrogen and reducing gas. |

| Porcelain class 2 | PT2 | 1400※2 | High-alumina(Al2O3)porcelain quality. There is little softening between the heat and good heat shock resistance. |

| Porcelain Class 1 | PT1 | 1500※2 | Semi-fused alumina(Al2O3)is sintered and superior to PT2. It is a little weak against quenching and rapid heating, and resistant to molten metal and combustion gas. |

| Porcelain special | PT0 | 1600※2 | It is superior in heat resistance and chemical stability than PT1. |

| Recrystallized silicon carbide | Y1 | 1600 | It is airtight, resistant to heat shocks, excellent in corrosion resistance and wear resistance under high temperature, for oxidation up to 1400℃ and temperature measurement in reducing atmosphere. |

| Self-bonding silicon carbide | Y2 | 1650 | In a neutral atmosphere, temperature can be measured up to 2200℃., and is hardly affected by acid and alkali. |

| Silicon carbide | Y3 | Up to 1500 Normal 1000 |

Its thermal conductivity is better than that of oxide type. It is excellent in thermal shock resistance by rapid heating and quenching. |

| Y4 | 1550 | Like the above, it has excellent performance and contains Si3N4. Especially suitable for molten aluminum temperature measurement. |

|

| Zirconia | ZR | 1800 | Thermal shock resistance comparable to that of recrystallized alumina and airtight. Chemically stable against strong alkalis, salts and molten metals other than alkali metals. |

In addition, we also handle special non-metallic protective tubes.

※1 Operating temperature refers to a temperature that can withstand prolonged use in air.

※By 2 JIS R 1401-1987.

Surface treatment of metal protective tube

Corrosion resistance

| Type | Thickness (mm) | Composition | Upper category temperature (℃) | Characteristic |

|---|---|---|---|---|

| Glass lining | t1~1.2 | Ordinary steel + glass | 450 | Good protection against acid and gas ingress. Limited to borosilicate glass (hard glass). Weak to heat shock. |

| Fluorinated resin coating | t0.3 | Metal + fluoropolymer | 120 | Concentrated hydrochloric acid, concentrated sulfuric acid, concentrated nitric acid, etc. can be used according to temperature conditions. |

Wear resistance

Stellite※1 processing, COLMONOY※2 processing, tungsten processing, etc. are processed for the abrasion resistance of metal protective pipes. For details, contact us upon request.

※1 Stellite is a registered trademark of KENNAMETAL Stellite Group.

※2 COLMONOY is a registered trademark of Wall Colmonoy Corporation.