Knowledge

Types and features of thermocouples

JIS Standard-Noble Metal Thermocouples

| Type | Features |

|---|---|

| B thermocouple (Platinum-Rhodium 30%-Platinum-Rhodium 6%) |

As the content of rhodium increases in platinum, the melting point and mechanical strength increase. In addition, the B thermocouple, which contains rhodium at both poles, shows little deterioration in the characteristics of thermoelectric power due to the diffusion of rhodium from the positive pole to the negative pole, which occurs when using the R and S thermocouples. In addition, it can be used continuously in oxidizing and neutral atmospheres, and even in a reducing atmosphere, in general, it has a longer life than R thermocouples. Because these thermocouples can be used at higher temperatures than R or S thermocouples, we recommend them especially when “Precision measurement and durability” are required in the high temperature range. However, in the low-temperature range, the accuracy is inferior due to the extremely low thermoelectromotive force, and it is not suitable for use at temperatures below 600℃. Compensation lead wires are not required in the normal temperature range. |

| R thermocouple (platinum-rhodium 13%-platinum) |

Thermocouple with high accuracy and low dispersion. It also has excellent oxidation and chemical resistance. This type of thermocouple is also used as a standard. However, avoid using in a vacuum or reducing atmosphere (especially hydrogen and metal vapor). |

| S thermocouple (platinum-rhodium 10%-platinum) |

JIS Standard-Base Metal Thermocouples

| Type | Features |

|---|---|

| N thermocouple (Nicrosil–Nisil) |

It is a thermocouple developed to compensate for the shortcomings of K thermocouples, which have been widely used for many years. It is superior to K thermocouples in oxidation resistance and long-term stability, and it has been proven that the long-term drift of thermoelectromotive force is 1/2 to 1/3 of that of K thermocouples at high temperatures of 1000℃ or higher, and that it can be used for a relatively long time even at 1250℃. Also, it is not suitable for use in a reducing atmosphere, as is the case with K thermocouples. |

| K thermocouple (Chromelic※1-Almel※1) |

It is currently the most used and reliable thermocouple for industrial use. This thermocouple has relatively excellent heat and corrosion resistance, and in addition to being able to be used at temperatures up to approximately 1200℃, features good linearity in electromotive force characteristics. Chromel※1wires deteriorate when the partial pressure of oxygen is low. Selective oxidation called “Green Rot” occurs, which greatly reduces the electromotive force in a short period of time and may cause a large error. Therefore, due care must be taken when specifying the product. It is also extremely vulnerable to sulfur gas, and deteriorates in thermoelectric power and mechanical strength in a short period of time. |

| E thermocouple (Chromelic※1-Constantan) |

Industrial thermocouples have high electromotive force characteristics and low thermal conductivity, which reduces thermal conduction errors and enables high-resolution measurements. Furthermore, it is superior in oxidation resistance and corrosion resistance compared with J thermocouples whose operating temperature range is close. It is widely used in large thermal power plants, nuclear power plants, etc. Also, it is not suitable for use in a reducing atmosphere, as is the case with K thermocouples. |

| J thermocouple (Iron-Constantan) |

It is resistant to reducing atmospheres such as hydrogen and carbon monoxide, and is stable because of its weak association with carbon. It is also characterized by its thermoelectric power characteristics being the next highest for E thermocouples, making it a relatively inexpensive thermocouple. Use caution when using the product because iron is heavily oxidized in an oxidizing atmosphere containing moisture. |

| T thermocouple (Copper-Constantan) |

T thermocouples are used in the relatively low temperature range (-200 to 300℃) and are suitable for use in weak oxidizing or reducing atmospheres. It has good linearity from room temperature to low temperature and stable thermoelectromotive force, and is often used in laboratories, etc. because of its ease of handling. Since the thermal conductivity of the thermocouple is high, sufficient attention should be paid to measurement errors caused by insufficient depth of thermocouple insertion. As copper is easily oxidized at high temperatures, there is a limit to the measured temperature. |

| C thermocouple (Tungsten/Rhenium 5% -Tungsten/Rhenium 26%) |

A thermocouple developed for use in high-temperature ranges, capable of measuring temperatures up to approximately 2300℃. Tungsten is easily oxidized and is subject to use in a reducing or inert gas or vacuum. As a result of the revision in fiscal 2015, we joined JIS standard. |

※1:Armel ALUMEL® , Chromel CHROMEL® are registered trademarks of Concept Alloys, Inc.

Out of JIS

| Type | Features |

|---|---|

| 40:20PR thermocouple(Platinum/rhodium 40% -Platinum/rhodium 20%) |

It can be used at higher temperature than B thermocouple, but electromotive force becomes smaller. Handling and use is the same as B thermocouple. |

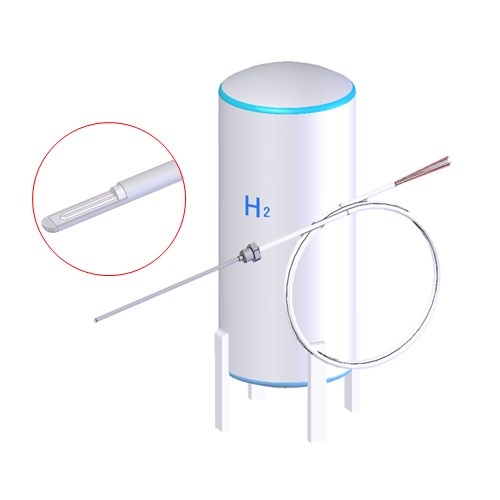

| PLII thermocouple (palladium/platinum/gold-palladium/gold) |

It is resistant to reducing atmosphere and can be used in hydrogen atmosphere. |

| Gold/chromel※1thermocouple (Gold/Iron-Chromel※1) |

Thermocouple developed for cryogenic use, capable of measuring temperatures up to-269℃. |

※1:Chromel CHROMEL® is a registered trademark of Concept Alloys, Inc.