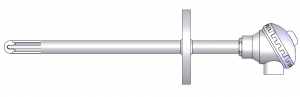

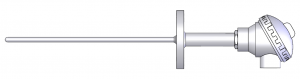

Sheath type thermocouple

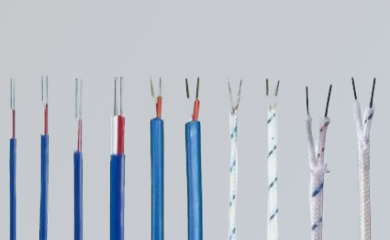

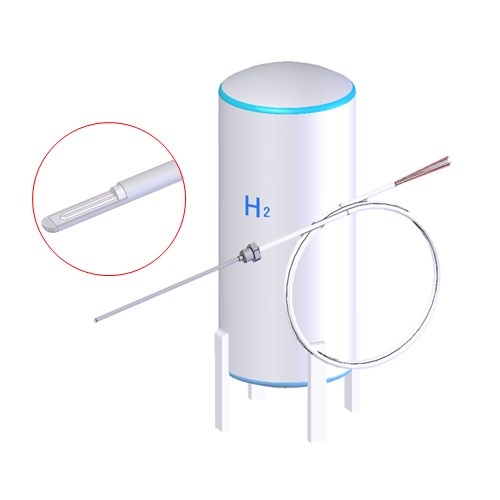

Metal Sheathed thermocouple is comprised of metal sheath in which the thermoelectric elements are embedded in highly compacted magnesium oxide (MgO) insulation.

The construction guarantees a superb insulation quality and high resistance to pressure, and has, in addition, an excellent flexibility, which has been given to it by annealing in a proper method