In the iron and steel manufacturing process, blast furnaces that use iron ore and coke emit many greenhouse gases during manufacturing. Recently electric furnaces that use scrap iron as a raw material have been reviewed as they emit less greenhouse gases than blast furnaces at the same production volume, even if they consume a large amount of electricity.

Refractories are also used in electric furnaces, and it is necessary to control the thickness of the refractories. If the refractory is eroded, the surface temperature of the inductor case increases. To check the erosion condition temperature can be monitored.

Solution

Detachable PAD sheathed thermocouple for measuring the inductor case

- Thermocouple

- Special products

- Steel & Nonferrous Metals

- Furnace

Features

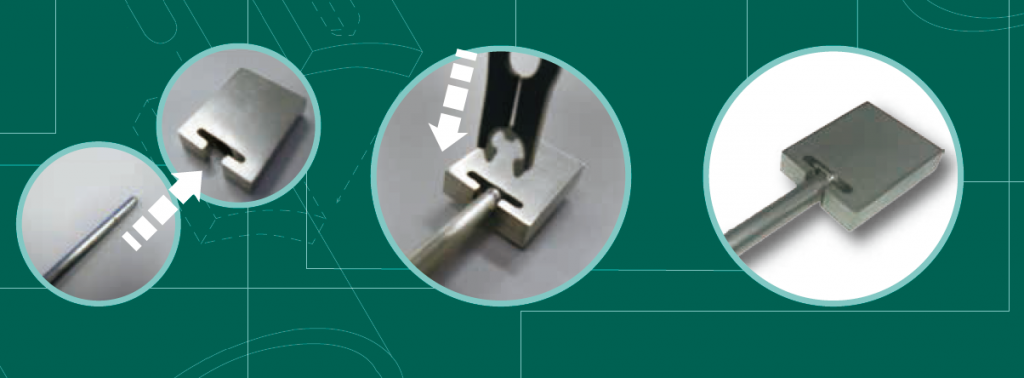

In many cases, a stainless-metal PAD is welded to the top of a sheath-type thermocouple to measure the surface-temperature of the inductor case. The sheath thermocouple may be disconnected and discarded when moving the furnace during a turnaround shutdown, etc., but this sheath thermocouple can be used continuously without being discarded during a turnaround shutdown by adopting a detachable PAD type.