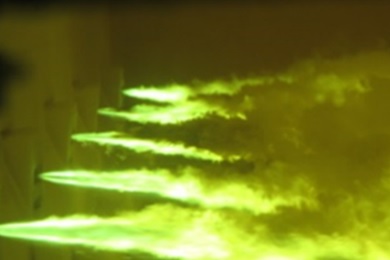

When manufacturing glass products, glass materials are mixed and melted at high temperatures in a glass melting furnace.

Generally, a platinum cap is placed over a ceramic tube to control the temperature of the molten glass, and a precious metal thermocouple is used as the temperature sensor, but the high temperature causes severe wear and tear, and the running cost of the precious metal thermocouple is high. However, the use of fiber-radiation thermometers instead of precious metal thermocouples can reduce costs.

Solution

Fiber thermometer with furnace bottom blackbody tube for glass melting furnace (IS50-LO/GL)

- Pyrometers

- Daily life

- Furnace

Features

The bottom of a ceramic tube with a platinum cap inserted into the bottom of a glass melting furnace is coated with black body paint to create a pseudo-black body, and infrared rays from this spot are captured to realize accurate temperature measurement. The fiber-type system does not require cooling at temperatures as low as 200°C.

We propose a large cost reduction by implementing this system.

Fiber thermometer IS50-LO/GL