Knowledge

What is RTD?

The electrical resistance of metal conductors generally varies with temperature. A sensor that measures temperature by utilizing the property that electrical resistance changes with this temperature is called a RTD.

Features of RTD

The RTD used in industrial applications has the following features.

- Fast response.

- The stability and reproducibility are very excellent.

- Can obtain high accuracy

Structure and measurement method

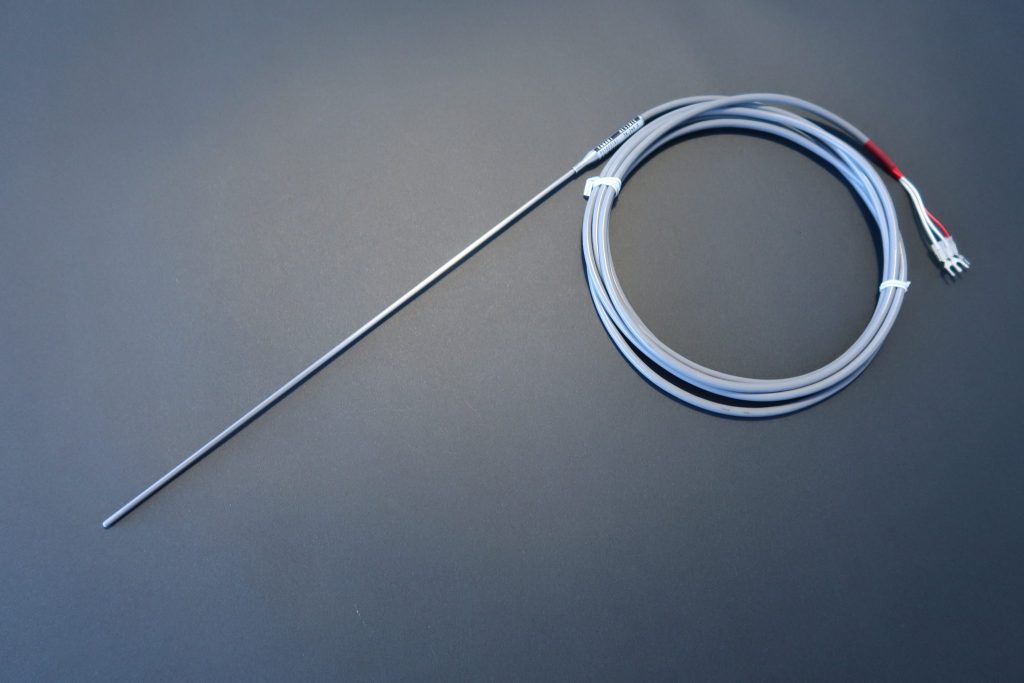

Structure of RTD

A RTD uses a resistance wire that captures the change in temperature as a change in electrical resistance as a temperature sensor. In general, a RTD consists of a resistor element, an internal conductor, a protective tube, and terminals.

How to measure RTD

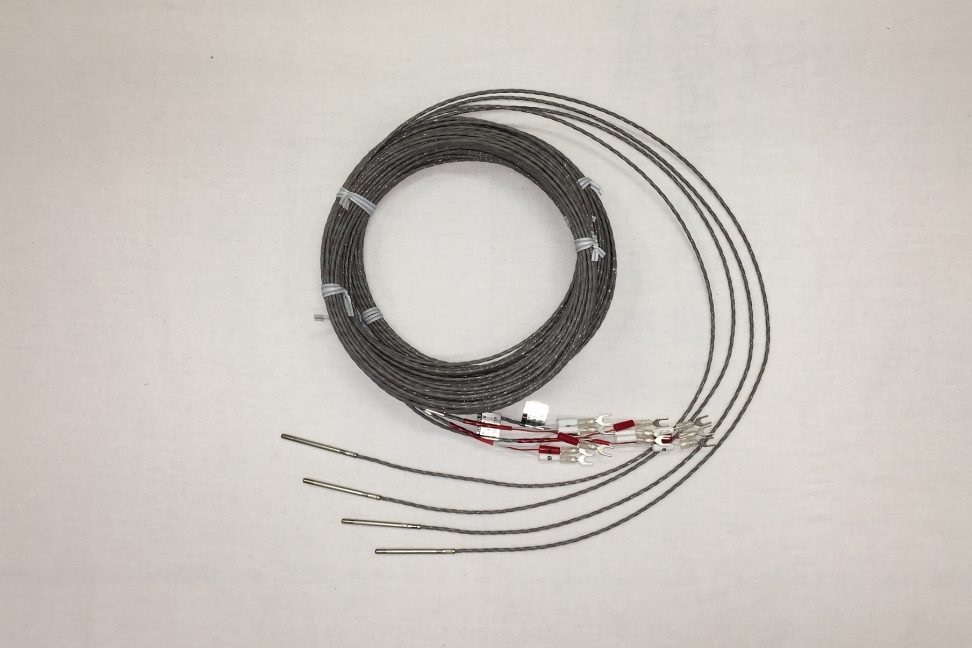

- 2-wire: Type code W

In terms of cost, it is less expensive than other types, but it is not suitable for measurements requiring high accuracy because it is affected by conductor resistance. - 3-wire: Type code X

Two conductors are connected at one end of a resistance element and one conductor is connected at the other end so that the influence of the conductor resistance can be eliminated. This is the most reliable measurement method adopted for industrial use using RTD. - 4-wire: Type code Y

This is the most accurate measurement method compared to the 2-wire and 3-wire types in which two conductors are connected to each other at both ends of the resistance element and the influence of the conductor resistance is eliminated. This type is higher in terms of cost.

Precautions for use

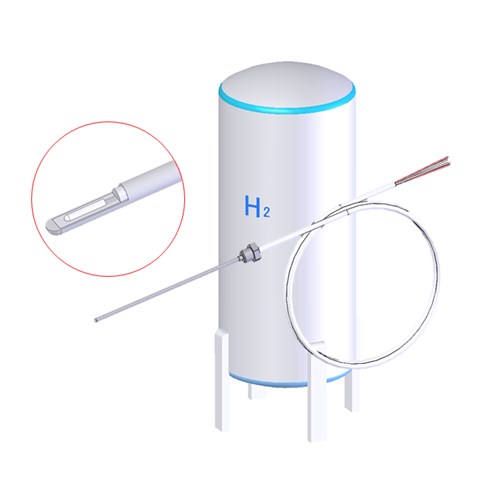

It is most important to select the proper RTD according to the application.

In order to correctly measure the temperature, in addition to the selection of the resistance element, it is necessary to pay attention to the selection of the protective tube considering the heat resistance, corrosion resistance, and earthquake resistance, the structure, and the mounting method (position), etc.